News

Dealing with Solenoid Coil Burnout & Operating Noise: A Guide to Causes & Professional Solutions

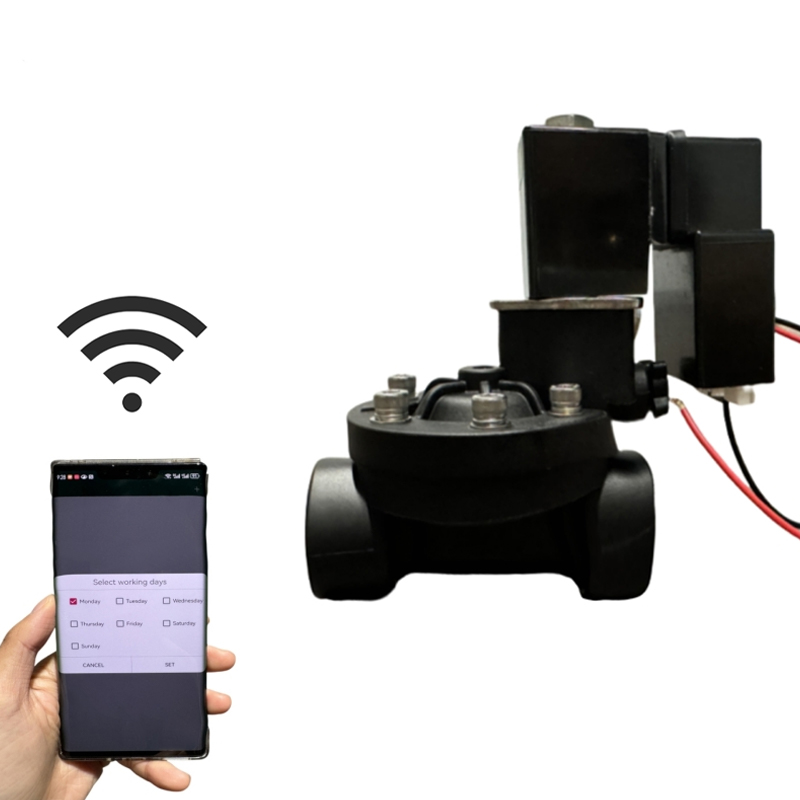

In the smooth operation of industrial equipment and automation systems, solenoid valves play a pivotal role. However, coil burnout or abnormal noise during energization are challenges frequently faced by engineers and procurement decision-makers. These issues not only cause unplanned downtime but may also indicate deeper system compatibility problems. This article delves into the root causes and provides professional, actionable solutions to help you prevent failures and optimize equipment reliability.

Core Issue 1: Causes of Coil Burnout & Countermeasures

Coil burnout is typically not an isolated event but the result of one or more stress factors within the system acting in concert.

1. Voltage Mismatch & Fluctuation

-

- The Core Problem: This is the most common cause of coil overheating. Continuously applying voltage higher than the coil’s rating causes excessive heat generation. Conversely, voltage that is too low may prevent the plunger from seating fully, resulting in a sustained high current draw, which also leads to overheating.

- Professional Solution: First, always verify that the coil’s rated voltage (e.g., AC 220V, DC 24V) precisely matches the power supply. Second, in areas with unstable grid voltage, investing in a voltage regulator for the solenoid valve supply is a cost-effective protective measure.

2. Excessive Ambient or Media Temperature

-

-

The Core Problem: The insulation class of a solenoid coil (e.g., Class F, Class H) defines its maximum temperature limit. When heat from the valve’s environment or the high-temperature media flowing through it (e.g., steam, hot water) is continuously conducted to the coil, its temperature can exceed the insulation’s limit, accelerating aging and leading to burnout.

-

Professional Solution: Accurately assess the maximum ambient and media temperatures. For high-temperature applications, it is essential to select a coil with a correspondingly higher insulation class (e.g., Class H) or a valve featuring a thermally isolated design that effectively shields the coil from the hot valve body.

-

3. Excessive Cycling or Continuous Duty

-

-

The Core Problem: Switching frequencies far exceeding design specifications, or applications requiring the valve to remain energized open for extended periods, cause the coil to generate heat continuously. Without sufficient time to dissipate, this heat accumulates and leads to failure.

-

Professional Solution: Review the operating cycle frequency of the application. For scenarios requiring long-term energization, it is recommended to select Alahot low-power consumption coils or utilize specialized solenoid valves with “pulse coil” or “latching” features. The low-power consumption coils can remain continuously energized for extended periods without generating heat. Lab tests have demonstrated that Alahot coils can operate continuously for more than one year with no observable coil overheating. Pulse coils are energized only at the moment of actuation and can be powered off immediately after, effectively eliminating any heat concerns associated with prolonged energization.

-

4. Moisture Ingress & Short Circuit

-

-

The Core Problem: In damp, humid, or condensing environments, moisture can penetrate the coil winding, compromising insulation and causing turn-to-turn short circuits. This creates localized spots of high resistance and intense heat.

-

Professional Solution: Specify a coil with an adequate Ingress Protection (IP) Rating for the installation environment. For instance, IP65 offers protection against dust and water jets, suitable for most industrial settings. For wash-down areas in food or pharmaceutical applications, IP67 or higher is advisable.

-

Core Issue 2: Causes of Operating Noise (Hum/Buzz) & Countermeasures

Abnormal noise during operation is not just a nuisance; it can be a precursor to performance issues.

1. Inherent AC Operation & Voltage Issues

-

-

The Core Problem: AC-powered solenoid valves inherently experience vibrational hum due to the alternating magnetic field (at 50/60 Hz), which is normal. However, excessively loud noise often points to insufficient voltage, resulting in inadequate magnetic force to hold the plunger firmly and quietly in place, causing chatter.

-

Professional Solution: The primary action is to measure and ensure the operating voltage is within ±10% of the rated value. Additionally, consider specifying coils with an integrated rectifier (diode bridge) circuit. This converts the supply to a smoother DC for the coil, significantly reducing vibration and noise.

-

2. Worn, Contaminated, or Misaligned Mechanical Components

-

-

The Core Problem: Wear on moving parts like the plunger, spring, or armature over time, contamination from media blocking free movement, or misalignment during installation creating binding forces can all cause irregular noise.

-

Professional Solution: Implement a scheduled maintenance program. For critical applications, plan for periodic cleaning or replacement of internal seals and springs. During installation, ensure proper pipeline alignment with the valve to avoid imposing stress.

-

3. Loose Components

-

-

The Core Problem: Simple hardware loosening, such as the coil housing or mounting nuts, can allow parts to resonate and rattle when the valve vibrates upon energization.

-

Professional Solution: Include checking and re-tightening all external fasteners as a standard step during maintenance shutdowns.

-

Our Professional Value: Proactive Prevention

Understanding these causes reveals that most failures can be prevented through correct initial selection and configuration. This is the core value a professional supplier provides.

For your next project specification, please consult with our application engineers and confirm the following key parameters. This allows us to recommend the most reliable and suitable solution:

1. Exact voltage and power type (AC/DC).

2. Ambient and media temperature ranges.

3. Expected operating frequency and duty cycle.

4. Site environmental conditions (humidity, dust, wash-down needs).

5. Any specific requirements for noise levels.

By ensuring precise application matching, we can work together to minimize the risk of unplanned downtime and ensure the efficiency and smooth operation of your processes.

English

English Español

Español