News

How to Diagnose and Troubleshoot Solenoid Valve Malfunctions

Typical Manifestations and Diagnostic Approaches for Solenoid Valve Malfunctions

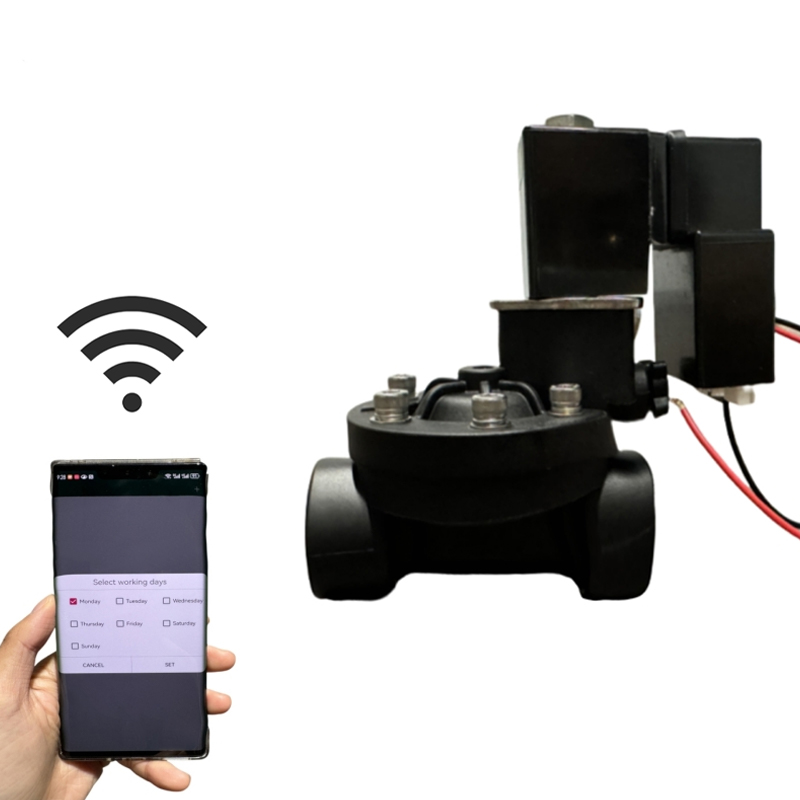

Solenoid valves are widely used in industrial automation, water supply and drainage, pneumatic and hydraulic systems. Malfunctions, such as “not operating” or “not closing,” are among the most common and easily causing system malfunctions. “Not operating” typically manifests as no response from the valve core after energization; “not closing” manifests as the medium continuing to flow after power is cut off. Diagnosing these problems should follow the basic approach of “external first, then internal; electrical first, then mechanical,” gradually narrowing down the fault range and avoiding blind disassembly or replacement.

Diagnosis and Troubleshooting of Electrical System Faults

Power Supply and Control Signal Inspection

Solenoid valves rely on a stable power supply and correct control signals to operate. First, confirm that the power supply voltage matches the solenoid valve’s nameplate parameters; AC and DC valves should not be interchanged. Use a multimeter to measure the voltage at the coil terminals and observe whether there is a significant change when switching on and off. If there is no voltage or the voltage deviation is too large, further check the controller, relays, PLC output points, and wiring terminals for looseness, oxidation, or burning.

Coil Damage or Abnormality

The coil is one of the core components of a solenoid valve. A burnt-out, short-circuited, or open-circuited coil will cause the solenoid valve to malfunction. The coil resistance can be measured with the power off and compared to the manufacturer’s reference value. If the resistance is infinite, the coil is open-circuited; if it is significantly lower, there may be an inter-turn short circuit. In addition, overheating, discoloration, or a burnt smell usually indicate that the coil has failed and needs replacement.

Troubleshooting Mechanical Structure and Valve Body Problems

Valve Core Sticking or Spring Failure

When the medium contains impurities, is corroded, or has not been used for a long time, the valve core is prone to sticking. This will cause the valve to not operate when energized, or to fail to reset and close after power is off. After disassembling the valve body, check the valve core surface for dirt, scratches, or deformation, and check the return spring for fatigue, breakage, or loss of elasticity. Cleaning and proper lubrication can restore minor sticking, but severe wear requires replacement.

Seal Aging and Internal Leakage

In many cases, a solenoid valve that cannot close is not due to a failure of the valve core to reset, but rather the inability of the sealing surface to form an effective seal. Aging, swelling, or corrosion of rubber seals can cause internal leaks, allowing the medium to continue flowing even when power is off. Such problems typically require replacement of the seal and verification that the selected material is compatible with the medium’s temperature and chemical properties.

Influence of Media and Operating Conditions

Insufficient or Excessive Differential Pressure

Some pilot-operated solenoid valves have specific requirements for minimum operating differential pressure. If the system differential pressure is too low, the valve will not open even when energized; conversely, if the differential pressure or pressure exceeds the design value, the valve core may fail to close. Diagnosis should be performed using system pressure gauges to verify whether the actual operating conditions match the valve selection parameters.

Media Temperature and Cleanliness

High-temperature media may accelerate coil aging and seal deformation; media containing particles, oil, or crystals can easily clog the tiny channels inside the valve. For such conditions, a filter should be installed upstream of the solenoid valve, and regular drainage and maintenance should be performed to reduce the probability of failure.

Common Fault Phenomena, Causes, and Solutions

| Fault symptoms | Possible causes | Recommended troubleshooting |

| No action when powered on | No power supply or damaged coil | Check the power supply and replace the coil |

| Does not shut off when power is off | Aging seals or stuck valve core | Clean or replace the seals |

| Slow action | Dirty media or fatigued spring | Improve media conditions and inspect the internal components |

Practical Recommendations for Systematic Troubleshooting

-

Before disassembly, record the power on/off status and pressure conditions to facilitate troubleshooting.

-

Start with externally measurable parameters, such as voltage, resistance, and pressure, before proceeding with internal inspection.

-

When replacing parts, use original parts or parts with identical specifications whenever possible to avoid “fitting but not compatible” issues.

-

Establish a regular maintenance schedule, especially for solenoid valves in critical positions or those with high-frequency operations.

By using these methods, the root cause of solenoid valve malfunction or failure to close can be quickly located in most cases. Compared to relying solely on experience, systematic diagnostics not only reduces downtime but also significantly extends the lifespan of solenoid valves and the entire system.

English

English Español

Español