-

This brass app-controlled solenoid valve is designed for remote automation and intelligent fluid control across a wide range of applications. With ultra-low power consumption (only 0.5W), it supports ...

-

Crafted from durable 304 stainless steel, this App remote control solenoid valve is engineered for long-term performance in demanding environments. It supports multiple control modes—direct acting, la...

-

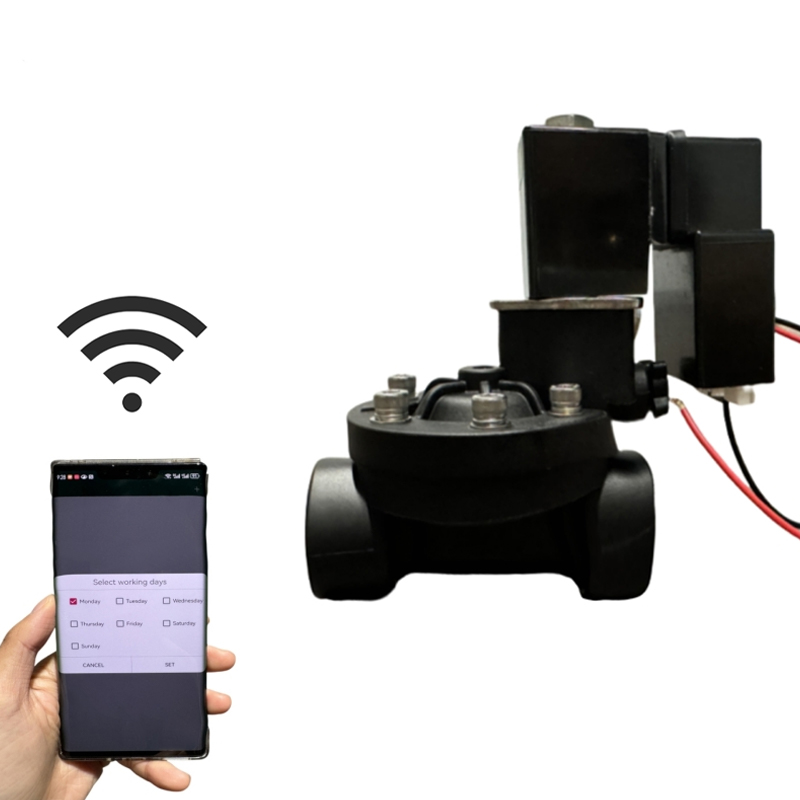

Made from corrosion-resistant engineering plastic, this App-enabled solenoid valve offers a lightweight and cost-effective solution for smart fluid control systems. With ultra-low power consumption of...

-

This brass App timer control solenoid valve is engineered for smart fluid management systems that require precise, scheduled operation. Featuring integrated app connectivity and a programmable timer f...

-

This solenoid valve is made from high-grade 304 stainless steel and supports smart app-based timer control, enabling precise and automatic valve operation based on scheduled times. With only 0.5W of p...

-

This solenoid valve features a lightweight plastic body and supports remote app-based timer control. It enables scheduled valve operation according to predefined time settings, which helps optimize fl...

-

Brass App Temperature Control Solenoid Valve enables automated flow regulation based on temperature feedback via app-integrated control. Designed for use in systems requiring responsive fluid manageme...

-

304 Stainless Steel App Temperature Control Solenoid Valve is designed for automated fluid control systems that respond to temperature fluctuations. With app integration, users can remotely manage val...

-

Plastic App Temperature Control Solenoid Valve supports temperature-based automation through app-integrated control logic. It works in coordination with embedded sensors and cloud communication protoc...

-

Brass App Pressure Control Solenoid Valve integrates pressure sensing and app-based control to support intelligent pressure regulation in fluid systems. With built-in support for NB-IoT, MODBUS, and o...

-

304 Stainless Steel App Pressure Control Solenoid Valve offers automated pressure regulation through app-based remote control and integrated pressure sensing. Designed for precision fluid control in d...

-

Plastic App Pressure Control Solenoid Valve integrates remote pressure sensing with app-based control to deliver responsive pressure regulation in low to medium demand systems. The lightweight plastic...

Smart App Wifi Solenoid Valves Manufacturers

We integrate sensors (temperature, flow, pressure) and full communication stacks (NB-IoT, MODBUS) within the valve body.

This is not bolt-on integration — it’s true unification, making each valve capable of sensing, decision-making, and autonomous control.

Our company enables global control through diverse technologies, including remote operation worldwide, scheduled automation, temperature regulation, flow control, pressure management, humidity monitoring, and more. Custom technical solutions are available upon request.

Alahot (Zhejiang) Technology Co., Ltd. is a technology-driven manufacturer of solenoid valves. As Smart App Wifi Solenoid Valves Manufacturers and App Global Control Solenoid Valves Factory in China, we integrate electromagnetic control, fluidic design, communication protocols, and software engineering to build valves with intelligent sensing and precise control.

We deliver more than components—we deliver control units that can be embedded into your system, sensing, responding, and collaborating to enhance overall performance and value.

At Alahot, technology is not a buzzword. It's a verifiable ability to solve. We’ve delivered solutions that others couldn’t.

From battery-powered irrigation systems, to closed-loop HVAC controls, to ultra-quiet miniature valve assemblies for medical devices. These weren’t product tweaks—they were full-stack, co-engineered systems from hardware to software. We can deliver your first sample in two weeks—or keep optimizing its every detail for five years.

News and Information

Industry knowledge

Remote Scheduling Strategies for Smart Solenoid Valves

Smart app WiFi solenoid valves enable precise remote scheduling of fluid or gas control systems. By programming activation cycles through a mobile app, users can optimize system efficiency and reduce energy consumption. Advanced scheduling features allow staggered operation across multiple valves, preventing pressure surges and reducing wear on connected equipment.

- Implementing flow-based schedules can dynamically adjust valve opening based on real-time demand.

- Using seasonal schedules for irrigation or HVAC systems ensures optimal resource utilization.

- Integration with smart meters allows automatic adjustment based on consumption patterns.

Security and Encryption in App Global Control Valves

Global control valves accessible via apps require robust cybersecurity measures. Weak security can lead to unauthorized access, which may cause operational hazards or system inefficiencies. Encrypted communication protocols, secure authentication, and firmware update mechanisms are essential for maintaining system integrity.

- End-to-end encryption ensures that data sent between the app and valves cannot be intercepted.

- Multi-factor authentication for users prevents unauthorized app access.

- Regular OTA (Over-the-Air) firmware updates patch vulnerabilities and maintain compliance with security standards.

Optimizing Network Connectivity for Multiple Valves

When controlling multiple smart valves across large areas, network stability becomes a critical factor. WiFi mesh networks, signal repeaters, and dedicated IoT hubs can ensure seamless communication. Proper network configuration prevents delayed actuation or missed commands, which is particularly important for automated fluid management systems.

- Segmenting devices into subnetworks reduces congestion and improves response times.

- Signal strength monitoring in the app can proactively detect connectivity issues.

- QoS (Quality of Service) prioritization ensures critical valve commands are executed without delay.

Integration with Smart Home and Industrial IoT Systems

Smart solenoid valves can be integrated into larger IoT ecosystems for comprehensive monitoring and control. Data collected from valves can be used for predictive maintenance, flow optimization, and energy management. Compatibility with standard protocols like MQTT or Modbus enhances interoperability with other devices.

- Integration allows automatic shutdown during leak detection or abnormal flow conditions.

- App-based dashboards provide centralized visibility of multiple valves in real time.

- Analytics can detect patterns that optimize system performance and extend valve lifespan.

Energy-Saving Control Algorithms for App-Operated Valves

Energy consumption can be significantly reduced by applying intelligent control algorithms to app-controlled valves. Algorithms that modulate valve opening duration, adjust flow rate, or implement predictive cycles based on usage patterns improve both efficiency and equipment longevity.

| Control Method | Energy Savings | Application |

| Pulse Modulation | 15-20% | Irrigation systems, cooling loops |

| Predictive Scheduling | 10-15% | Smart home water control |

| Adaptive Flow Adjustment | 12-18% | Industrial fluid systems |

Troubleshooting Connectivity and App Issues

Despite advances in WiFi-enabled valves, connectivity and app performance issues can occur. Systematic troubleshooting ensures reliable operation and minimizes downtime.

- Checking firmware compatibility between the app and valve is essential for proper control.

- Ensuring WiFi signal strength meets minimum requirements prevents delayed or missed commands.

- Monitoring battery levels or power supply stability in remotely located valves avoids unexpected shutdowns.

English

English Español

Español