Industry knowledge

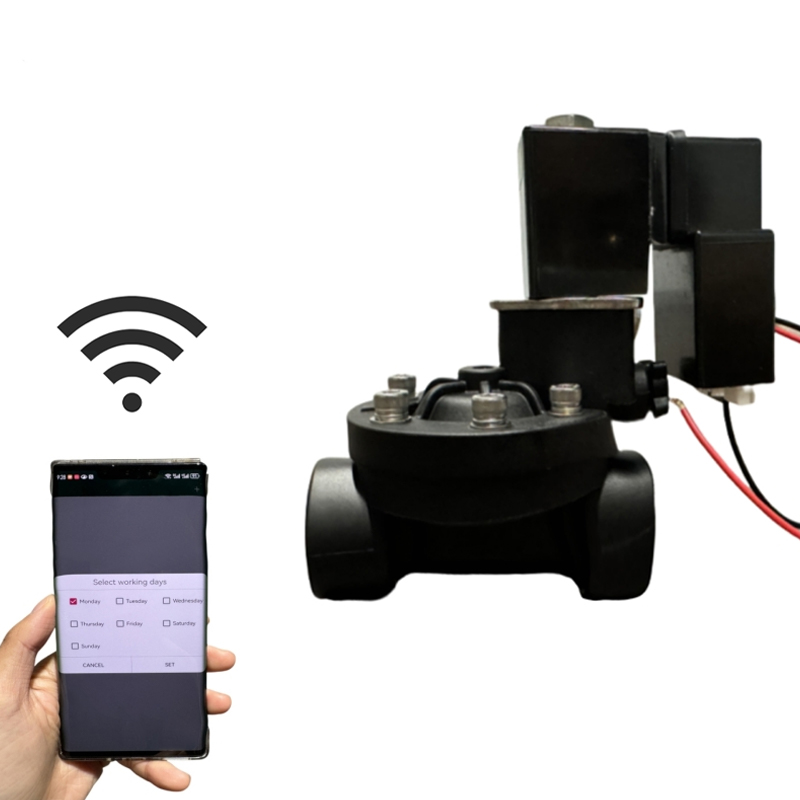

Dynamic Temperature Regulation with App-Controlled Valves

App temperature control solenoid valves provide precise modulation of fluid flow based on real-time temperature readings. This allows users to maintain consistent system temperatures in HVAC, heating circuits, or industrial processes. Advanced algorithms in the app adjust valve opening gradually to prevent thermal shocks and maintain energy efficiency.

- Proportional control can adjust valve position based on temperature deviations, rather than simple on/off switching.

- Integration with multiple sensors ensures uniform temperature distribution across zones or circuits.

- Adaptive control routines in the app can learn system behavior to predict and preempt temperature fluctuations.

Preventing Overheating and Freeze Conditions

Temperature control solenoid valves can protect systems from overheating or freezing by automatically adjusting flow or shutting off sections based on app-monitored thresholds. This is critical in environments with extreme or fluctuating temperatures.

- High-temperature limits in the app prevent valve operation above safe fluid temperatures.

- Low-temperature protection can redirect or isolate flow to prevent freezing in pipes.

- Alarm notifications and remote intervention options allow immediate corrective action if thresholds are breached.

Optimizing Energy Efficiency in Temperature-Controlled Systems

Efficient energy management is achieved when app-controlled valves operate in tandem with temperature sensors and predictive algorithms. By precisely modulating flow based on real-time conditions, systems avoid unnecessary heating or cooling cycles.

- Gradual valve opening reduces peak energy demand compared to fully on/off operation.

- Time-of-day scheduling can align heating or cooling with occupancy patterns to save energy.

- Analytics from the app allow fine-tuning of control parameters to maximize efficiency over time.

Monitoring and Reporting Valve Performance

App Temperature Control Solenoid Valvesoffer comprehensive monitoring of valve activity and temperature trends. Performance reports help detect anomalies, predict maintenance needs, and ensure system reliability.

| Parameter |

Recommended Range |

Application |

| Valve Response Time |

≤100 ms |

Rapid thermal adjustment |

| Temperature Accuracy |

±0.5°C |

HVAC & industrial heating |

| Duty Cycle |

≤50% |

Continuous control systems |

Troubleshooting Temperature-Controlled Valve Systems

Even with precise app control, temperature-regulated valves may experience operational issues. Regular diagnostics and system checks are essential for maintaining performance and safety.

- Verify sensor calibration and app connectivity to ensure accurate temperature readings.

- Inspect valve seals and plungers for wear that may affect flow modulation.

- Monitor app logs for repeated temperature deviations or delayed valve response to detect underlying issues early.

Multi-Zone Temperature Control Strategies

App-controlled solenoid valves can manage multiple temperature zones simultaneously, allowing tailored heating or cooling for different areas. Coordinating these zones improves comfort, process efficiency, and energy usage.

- Individual zone sensors enable precise temperature adjustments per area or circuit.

- Priority control logic ensures critical zones maintain target temperatures during high demand.

- Cross-zone analytics detect imbalances and automatically adjust flow to optimize overall system performance.

English

English Español

Español