News

Latching Operated Solenoid Valves: Applications, Design, and Optimization

1. Key Advantages and Applications of Latching Operated Solenoid Valves

Latching operated solenoid valves are designed to maintain their open or closed state without continuous electrical power. Unlike traditional solenoids, which require constant energy to maintain position, latching valves use a short pulse of current to change states. This feature offers significant energy savings, especially in systems with frequent actuation or long hold times. They are widely used in water treatment, pneumatic systems, HVAC, and automated manufacturing lines where energy efficiency and reliable position holding are critical.

- Industrial fluid control systems where valves remain in one state for extended periods.

- Pneumatic automation requiring precise positioning without power drain.

- Remote or battery-powered applications, including irrigation and HVAC zones, where energy efficiency is crucial.

2. Design Principles of Latching Solenoid Valves

The design of latching operated solenoid valves revolves around the magnetic latching mechanism. Typically, a permanent magnet is combined with an electromagnetic coil. When a pulse is applied to the coil, the plunger or armature moves to the desired position and is held there by the permanent magnet. The direction or polarity of the pulse determines whether the valve opens or closes. This system reduces heat generation, extends coil life, and minimizes energy consumption compared to continuous-duty solenoids.

2.1 Magnetic Latching Mechanisms

Magnetic latching mechanisms use a combination of electromagnetic force and permanent magnets to hold the valve position. Proper magnet selection and coil design ensure that the valve responds reliably to pulse signals, even under varying fluid pressures. Engineers must carefully balance magnetic force to prevent unintentional movement while allowing smooth actuation.

2.2 Pulse Duration and Voltage Considerations

The pulse duration and voltage applied to latching solenoids must be optimized for reliable operation. Excessively short pulses may fail to actuate the valve fully, while overly long pulses increase energy consumption and generate unnecessary heat. Manufacturers usually provide recommended pulse ranges based on coil resistance, voltage, and ambient temperature. Implementing precise pulse control in automated systems enhances repeatability and reduces maintenance needs.

3. Energy Efficiency and Cost Benefits

Latching solenoid valves are inherently energy-efficient because they require current only during state changes. This translates into substantial cost savings in systems with large numbers of valves or continuous operation. For battery-powered devices, the reduced energy requirement prolongs operational life and reduces the frequency of recharging or battery replacement.

- Up to 90% energy savings compared to continuous-duty solenoids in long hold applications.

- Reduced cooling requirements in dense valve arrays or confined spaces.

- Lower operational costs and extended system uptime for remote installations.

4. Material Selection and Fluid Compatibility

Material selection is critical for latching operated solenoid valves, as inappropriate choices can lead to corrosion, seal failure, or reduced valve life. Stainless steel and brass are commonly used for bodies, while PTFE and FKM are preferred for seals in chemically aggressive or high-temperature environments. Engineers must evaluate fluid viscosity, temperature, and chemical composition to select appropriate materials that maintain reliable operation.

4.1 Seal and Plunger Materials

High-quality seal materials ensure minimal leakage and long-term durability. For water and neutral fluids, EPDM seals are often sufficient, whereas aggressive chemicals require PTFE or FKM. The plunger material must resist wear, friction, and corrosion to maintain consistent response over thousands of cycles.

4.2 Valve Body Materials

Valve body materials must handle pressure, thermal expansion, and chemical exposure. Stainless steel is ideal for aggressive environments, while brass is suitable for general industrial fluids. Correct material selection prevents premature failure, ensures reliability, and simplifies maintenance schedules.

5. Installation Best Practices

Proper installation is essential for achieving the full benefits of latching solenoid valves. Valves must be mounted in orientations compatible with their design, with careful attention to flow direction, pressure ratings, and vibration isolation. Electrical connections should follow manufacturer specifications for pulse control, voltage, and current limits.

- Use flow direction indicators to ensure correct fluid path and prevent damage to seals.

- Provide accessible mounting for inspection, maintenance, or coil replacement.

- Ensure proper grounding and insulation to prevent electrical interference or coil burnout.

6. Troubleshooting and Maintenance Strategies

Although latching solenoid valves are low-maintenance, operational issues can arise. Common problems include failure to actuate, leakage, or inconsistent response. Systematic troubleshooting helps maintain reliable operation and extend valve life.

6.1 Common Issues

- Pulses of incorrect voltage or duration leading to incomplete actuation.

- Debris accumulation inside the valve body or on the plunger surface.

- Worn or chemically degraded seals causing leakage or reduced holding force.

6.2 Maintenance Recommendations

- Regular inspection and cleaning of valve internals to remove particulates or sediment.

- Periodic verification of coil and electrical connections to ensure proper pulse delivery.

- Replacement of seals and plunger components according to operating hours and fluid conditions.

7. Performance Metrics and Selection Guidelines

Selecting the right latching solenoid valve involves evaluating several performance metrics, including response time, pressure rating, and duty cycle. Engineers should consider both electrical and hydraulic requirements to ensure reliable operation under all anticipated conditions.

| Parameter | Typical Range | Application |

| Response Time | 10–50 ms | High-speed automation |

| Pressure Rating | 0–10 bar | Water, air, and general fluids |

| Duty Cycle | Continuous intermittent | Battery-powered or energy-sensitive applications |

8. Emerging Trends and Future Applications

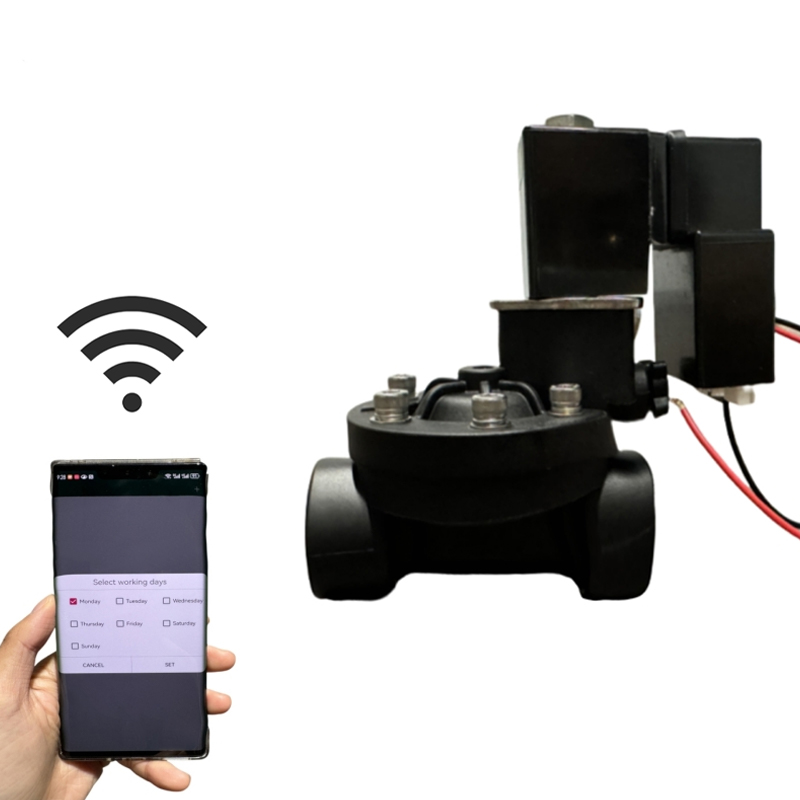

Latching operated solenoid valves are increasingly integrated with smart control systems, IoT devices, and remote monitoring platforms. Future applications may include predictive maintenance, energy optimization analytics, and automated system adjustments based on real-time data. Their energy efficiency and reliable performance make them ideal for expanding industrial automation and sustainable fluid management solutions.

- Integration with cloud-based control systems for remote diagnostics and actuation.

- Use in renewable energy systems where battery operation and efficiency are critical.

- Smart predictive control based on flow demand, temperature, and pressure sensors.

English

English Español

Español